Common Knowledge on the Installation Process and Quality Control of Spiral Steel Silo

The installation process of spiral steel silo

Spiral steel silo is mainly composed of feed hole, roof platform, stiffener, roof cover, trim strip, pressing block, roof manhole, ventilation hole, temperature hole, fan base, fan, fan outlet elbow, roof ladder, guard rail, upper tension ring, high strength bolt, triangular block, seal strip of roof eaves, silo wall, reinforcement stiffener, stud, wall manhole, platform, ladder, ventilation pipe, outlet and other components.

The installation process of spiral steel silo includes as follows

Check pre-embedded components on silo base→Find center point of silo→Draw base line→Locate the rolling equipments→Fix running frame and supporting roller →Install roof platform to the calculated height→Roll silo body to reach 1m high (left and right)→Upcut silo roof→Install tension ring→Roll to reach the designed height →Withdraw equipments and materials→Downcut→Put down silo body→Make wall man hole→Fix reinforcement stiffener→Withdraw equipments and running frame

The installation of spiral steel silo is a top-down process in the sequence of silo rolling after roof making. The rolling and installing process of silo body is continuous control of production process. It is also the installation process of reinforcement stiffeners of silo wall in the meanwhile. When the silo is rolled to reach a certain height, the first ring of stiffeners shall be installed. And then when the silo is rolled to reach another certain height, the second ring of stiffeners shall be done. This kind of cycle shall be implemented until the steel silo is rolled to designed height.

Spiral steel silo mainly adopts 495mm wide steel coils, using advanced technology and equipments from Germany. It consists of the de-coiling machine, rolling machine, bending machine and supporting frame equipments. Under all the machines, the silo will be manufactured out multi through the method of one-time synthesis. During the construction, the de-coiling machine will be sent to the rolling machine, the latter will make the silo form its initial shape. Meanwhile, the steel plate will be bent into the required diameter arc of the silo. After passing bending machine, the steel plate will be bent, bitten and rolled together, forming a spiral 30~40mm wide undercut. In the rolling process of the silo body, the outside wall will form a spiral undercut that is 5 times more than the plate in thickness, which greatly enhances the carrying capacity of the silo body. Through the use of special equipments, Spiral steel silo is fully, mechanically and automatically finished with high speed, beautiful shape, light wall, good tightness and high strength and stiffness.

The quality control of the rolling process of steel silo

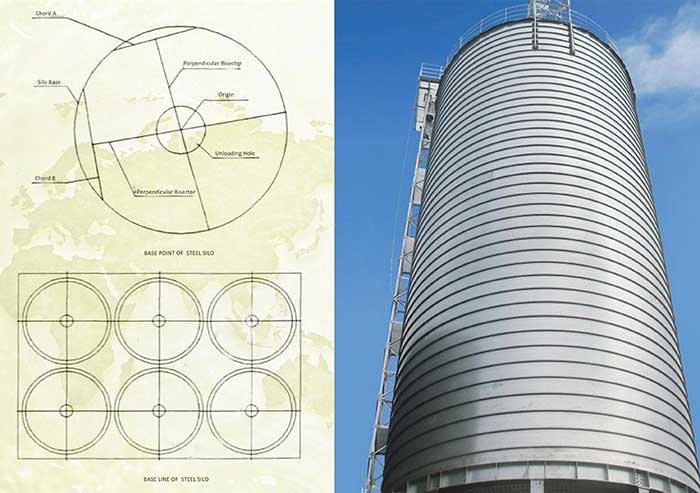

Determination of center point and base line of steel silo

The center point and base line of steel silo plays a vital role in quality. Before the installation, it is necessary to determine the center point of steel silo. Taking the center as the origin, we can draw the base line according to silo radius. On base of the radius of drop line (Put down the silo), we increase 250mm and draw the line that is the base line of running frame. In the process of construction, we must draw the line deeply to help to have a good control of putting down the silo body and position the center point and base line of running frame. These must meet the requirements of the designed drawings, whose diameter tolerance shall be ≤± 3D‰ and ≤±30mm (Here D stands for diameter).

Determination of the height of roof platform

The height of roof platform determines the building height of roof platform. The building height is too high or low to be favorable for the coming construction, which will lead to the wrong slope of the silo roof and influence the installation of the roof stiffeners. The preset height of roof platform can be gotten from the formula:

H=h+ (D/2+d/2) tgα

H—Height of the upper tangent line to the silo foundation

D—Diameter of steel silo

d—Diameter of roof platform (Diameter of upper tension ring)

α—Angle of roof inclination

The control of the circumference of silo body

Through the control of the circumference of silo body, we can indirectly control the diameter of the silo. In the production process, it's necessary to measure the circumference of each circle of the silo. There are two methods to achieve it. The methods are to use 1m long ruler to draw a line along the upper edge or the down edge of circular coil beginning from zero line and measure it. These two methods are respectively called upper drawing line method and down drawing line method. The result of measuring a circle length is the spiral length, which must be converted into the circumference. The circumference tolerance must be controlled in the range of 30mm. In practice, if the circumference beyond actual control will cause serious consequences, even the silo cannot be used. As the circumference becomes longer, this will cause the collision of support rollers and scratch the silo wall; as the circumference becomes shorter, this often leads that support rollers cannot support the silo wall. The unstable circumference will seriously affect the overall appearance of silo. When the tolerance of the circumference is beyond the limit, this should be adjusted in time into the allowable range.

The control of geometric dimensions and quality of the undercut

In the rolling process, the geometric sizes of the silo formation mainly depends on the tension degree, the upper and lower positions of the rollers of the rolling machine and the state coil feeding into the machine. These will determine whether we can get stable circumference. If the geometric sizes are not stable, the silo will be out of control, leading that the undercut is not tight and badly influencing the structure of the silo body.

Español

Español