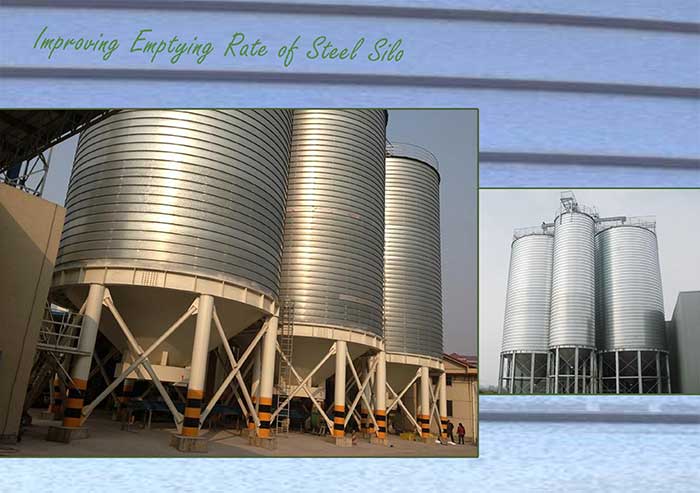

Some Key Factors on Improving Emptying Rate of Steel Silo

The emptying rate of steel silo refers to the ratio of unloaded material from the silo to the total material. It directly reflects practical performance of steel silo quality and is one of the most important performance indexes. When the unloading situation of a silo is in a deteriorated state, but the stored material left will be continuously accumulated more and more. This case will cause more accumulated material and slower unloading process, resulting in reduction of fluidization of effective fluidizing storing capacity of a silo. This is main reason of low emptying rate. The low emptying rate not only makes a steel silo play no good unloading effect and but also reduce economic benefits in use.

Main reason of affecting emptying rate of steel silo

Large steel silo commonly adopts pneumatic conveying mode to be unloaded, so the fluidizing capability of the material is depended on whether the silo can normally be unloaded. It is often influenced by the factors from many aspects, for example, long time of material overstocking, high humidity, moisture into a silo from outside air, wet bottom, improper operations by some working people. These make the material be bad at fluidizing capability.

Some key factors on improving of the emptying rate of a steel silo

Loosening material at the bottom of a silo

Generally, the material tonnage is too large and the material level is too high. These two points can cause the densities of bottom and material at the bottom of a silo to increase, which will result that the material closely presses the bottom of the silo and the fluidizing performance decreases. Without the activation for the material stored for a long time, the bottom material will lose fluidizing performance, resulting in unloading difficulties. This phenomenon generally occurs in off-season of material sales. During the season, the amount of material is much larger than that of selling. In order to avoid material being pressing tightly for a long time, a steel silo can regularly use pneumatic system of external circulation to loosen the material at the bottom.

Painting moisture proof materials

Generally speaking, powdery materials have respectively higher moisture content in themselves, so they are prone to result in the unloading failures when degradation of their fluidizing performance. In this regard, the users should strictly control their moisture content ratio and reduce it to the minimum before silo beginning to be loaded and. The drier materials are, the better their fluidizing capability is, and then the more difficult the materials at the silo bottom are pressed to in compaction. According to many practices, when the cement bottom is not completely dry, some users don’t take effective measures against the humidity, making the materials sticky into the blocks as the humidity degree of silo bottom get higher when rising damp. Thus, unloading difficulties occur. In addition, some users can’t wait natural dryness of unloading cone to start to load. Seen from the above, we should understand that the implementation of the bottom moisture proof measures is particularly critical. Our company has carried out strong and firm measures to guarantee the dryness of key parts of a silo. Painting moisture proof materials will make the surfaces of many parts smooth and clean and be conducive to conveying material circulation at the same time.

In order to maximize moisture proof effects, our company has organized the Design Dept., Quality & Safety Dept. and Research Dept. to participate in the sample test of 16 kinds of moisture proof materials. These materials can be divided into two or three categories according to the ratio; according to used materials, they can be divided into the categories of paint, Epoxy lipids and daub. In different ratios of materials, some are relatively good in the moisture proof effects, but all the basic material agents are manufactured by every company’s own preparation. Considering the constraints in the procurement and transportation, our company shall not use them. The moisture-proof effects of paint and daub materials are poor, we will not choose them. Seen from the test results of various moisture-proof effects and considering economic feasibility and other factors, with the consent of the consultations of many Depts., we have decided to adopt Epoxy lipids material which specific components are: E44 pure Epoxy lipids+T31hardening agent+ diluent (acetone). This kind of combination material is common chemical raw material and easy for procurement in regional construction site, which can save transportation time and reduce transportation risk. The material in construction will be used after finishing the cement surface of the unloading cone at the silo bottom and before installing the fluidization rods. At present as the moisture proof measures of steel silo bottom, they are actively promoted and we believe that they will play a more positive role.

As loosening the material at silo bottom, sometimes we will use air compressor to get high pressure of wind source. If the compressed air provided by air compressor can’t be effectively removed the moisture, this will also make the material get into adhesive blocks due to humidity increase. To take effective measures to reduce the moisture content of each link is in order to ensure the normal unloading rate.

Anyang Flyer Steel Silo Co., Ltd. has accomplished many complete projects of all kinds of spiral steel silos with abundant construction experience and expertise technical and designing engineers and workmen and help our client to provide with excellent silo manufacture. As one of the largest manufacturers of steel silo in China, we are committed to technological innovation, technology research and development, always leading among the industries. Manufacture the safest storage system of steel silo in the world; let FLYER products bring the customers more happiness.

If the client wants to understand or acquire relevant information, please feel free to contact with us. We here sincerely hope to receive your message because we know good communication with you is must-be way to start opening the door of success and cooperation.

Español

Español