Some Key Steps to Restrain the Mildew of Grain Stored in Steel Silo

In 1980s spiral steel silo just began to appear in China. At the early period, people showed great doubts about it because of the obvious characteristics of the silo, for example, the thinner wall, the temperature difference between inside and outside silo, not good enough sealing and other reasons. At the same time, people was worrying whether its service life can reach expected span or not due to thin steel sheets. After dozens of years of researches and practices, nowadays people is prone to use it on basis of solving the problems mentioned above. Of course, the problem of restraining the mildew of grain is included in, too. Next, we’ll talk about some steps to restrain the mildew of grain stored in steel silo.

Grain contains a lot of molds, but when grain moisture is lower and in safe range or grain temperature is normal, these molds are mostly in the suppressed state, which will not cause mildew. Once grain moisture changes (such as condensation) or grain temperature changes, especially water content increases, mold activity increases greatly and breathing function accelerates, these will result in accelerated growth and reproduction of grain molds and the mildew will be inevitable. How to cope with it? Yeah, the following steps are coming.

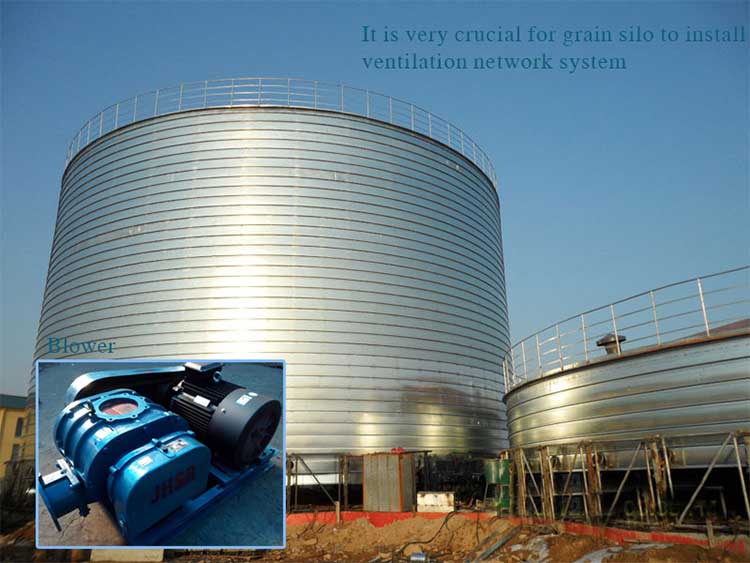

Mechanical Ventilation Technology

When grain is loaded completely, the silo should perform timely and routinely ventilation based on need and climate conditions to reduce the temperature and moisture of grain and increase the safety of grain storage.

The silo should adopt mechanical ventilation under natural low temperature in winter at the different stages to gradually reduce it to the low and proper temperature. After the ventilation, we should ensure the unloading holes and the ventilation holes at the bottom of the silo to be closed and heat insulation work finished. After the ventilation cooling the surface of the grain should be timely to cover and keep the sealing.

The rise of temperatures in spring and summer seasons, we should use the blowers on the silo roof to have the ventilation to expel heat accumulation of grain top in time, reduce storage temperature and solve temperature difference of the grain inside the silo.

The mechanical ventilation of steel silo should be equipped with ventilation automatic control system and manual operating system. The large movable fan should be with reduced voltage starting device and damping device. The movable car should the anti-displacement of the locking device. The airflow inlet of fan should be connected with the air inlet of silo by a soft hose. The natural air outlet on the roof of silo should be opened for ventilation. If necessity, we can also open the axial fan on the roof of silo at the same time.

In addition to the mechanical ventilation system, the steel silo should also be installed with one or two sets of single tube of ventilation system to deal with the local heating problem of grain heap.

Check Principles of Condensation and Mildew

Grain mildew check must include water content check. For the parts of the silo that water content is increased, we must strengthen the mildew check. When necessary, we can take a sampling for the inspection of mold content and change.

The condensation of grain is mostly because the great temperature difference among grain, silo and air. When hot air is cooled, the water vapor is condensed and changed into water. As the outside temperature was higher than grain temperature and then water vapor in the air meets cold grain, this will cause condensation in the surface of the grain; As the outside temperature was lower than grain temperature and then the hot air rises in grain and meets the cold air at the surface of the grain, this will cause the water vapor to condense on the grain surface. Therefore, during the seasonal transition, temperature changes rapidly, so we must strengthen the check work. Especially the time the temperature reaches the condensation temperature, we should pay more attention. We can make an accurate judgment from local data of condensation point.

The condensation point we should check mainly are the 5cm-30cm positions below grain surface, the positions near the wall of the sunny and shady side of silo and some dead parts.

Periodic check of condensation point should be determined on the grain situation and temperature changes. If the situation is stable and temperature difference between grain and outside temperature is far less than the temperature of condensation point, we can have a check every seven or ten days; if the grain moisture is higher or the difference between grain temperature and outside temperature is greater or has reached the temperature of condensation point, we should have a check every three days at least; if condensation phenomenon occurs, we should make the check at any time, and according to the situation, we should timely use mechanical ventilation and other measures to deal with.

Get In Touch With

Español

Español