Construction and Maintenance Problem of Cement Steel Silo in Summer

With the rapid development of cement equipment manufacturing industry, as an important role in the process of cement production, cement steel silo has been in boom. Because of its low cost, short construction period, small occupied area and many other advantages, it has gotten the popular recognition in the cement industry. But you may not understand that it has great relation for construction and maintenance of cement steel silo in different season. In summer there are some serious questions with the cement steel silo.

Construction Problems of Steel Silo in Summer

1. Bad Natural Environment

Summer is a special construction season with the climate characteristics of high hot temperature, more lightning and storm rain, so you should do a good job of preventive measures of lightning, heavy rain and other weather disasters.

2. Safety of Power Use

In hot summer, due to the weather, the workers wear less and there’s much sweat on the skin, this correspondingly increases the risk of electric shock. In addition, during this time it is humid and rainy. The insulation performances of the electrical equipments are reduced. This makes the summer become the peak season of electrical safety accidents. You should pay attention to electrical safety and make full preparation for prevention work, which is particularly important. In the rainy season you should pay attention to the on-site reliable inspection of electrical grounding and neutral connection of electrical equipments. All kinds of outdoor distribution box, electric welding machine have to be completely implemented rain-proof measures.

3. Sunstroke Prevention

The summer weather is dry, so it is a good season for construction. The workers are prone to work overtime for construction period, which will cause them to be continuous to overwork. This may arouse sunstroke. Therefore, the project department should pay attention to the relevant preventions to eliminate safety hazards.

4. Pressure Vessel Safety

Welding and cutting in the construction process are regular working operations. The gas vessels are placed directly in the construction site, which is the practice of construction project. The high summer temperatures, the temperature of high pressure gas will rise under sun irradiation, so gas volume will expand. This will be a serious explosion factor and very possible to cause the casualties and property losses.

5. Always Use Personal Protective Equipment (PPE)

In order to protect construction workers in the safety of construction process, they must wear personal protective equipment. Generally these articles are relatively thicker, just like water insulated gloves, insulated shoes, safety belts and so on. Wearing these articles will make the workers feel hotter in the swelter, so some of them prefer to be undressed in the working process. So if the danger were coming, the most basic protection is not to be with, which will make a great damage accident become more serious.

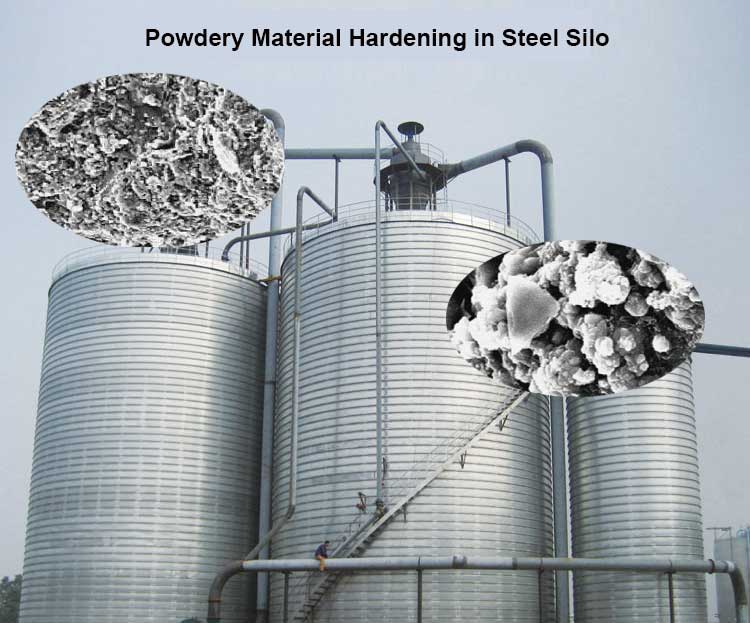

Maintenance Problem of Cement Steel Silo in Summer

Cement stored in the steel silo for a long time may change its performance, which is tested by the experiments.

A. the reaction between cement and water vapor in the air is carried out step by step;

B. the strength of cement under the conditions of different curing times will a bit increase in the following three months. After three months, the strength will decrease a bit and then greatly, and at last its nature has ultimately changed, resulting that the curing time cannot be measured.

C. With the extension of storage period, the SO3 of content will gradually decrease and the setting time will also increase.

D. Severe cold, dry and windy season, we can say, is good for cement storage. In winter the weather is cold and natural environment in the air is very dry, so cement is in a frozen state, which will reduce the moisture absorption of cement to some extent. In spring wind will take away the moisture in the air, reducing the contact of cement and water vapor. So just there is little influence on the performance of cement.

Many users feel that the cement steel silo shall not easily get rusty or corrode. But the summer is much rainy and the moisture content in the air is relatively higher, so it is easy for water combined with iron and steel. This will be easy to cause rust and corrosion. Therefore, you can take some measures to reduce the harm to large cement silo. You should always check all parts of the surface of cement silo. If you found corrosion or rust, you should quickly deal with them, for example, brush anti-corrosion paint. The method of corrosion protection is not the same to anti-rust measures and the index is not the same, either. You must be carried out in accordance with the standard of rust and corrosion protection.

Sometimes the collapse of cement silo is not because of quality problem and can be attribute to season. There are many risks to the collapse in summer. For example, the bolts and nuts are easy to rust. If they are not found in time, they may fall off, which is easy to cause collapse. So you should always check the bolts and nuts timely and make necessary replacement, especially for the important parts of the bolts and nuts. In use, you may not pay much attention to the safety problem of supporting legs cement silo. In summer, due to the legs are buried in the soil to support the cement silo, and then rain will make soil loose possibly, causing the legs could not support the cement silo. So if it rains in summer under many circumstances, you should check the leg parts.

With the extension of storage time, it will add bulk density of cement in cement silo, and due to air isolation of large steel silo wall, the cement basically belongs to the vacuum sealed. Practice has proved that the cement stored in large steel silo for more than two years, its compressive strength is basically unchanged in addition to slightly longer setting time and the slightly decreased flexural strength. The sealing effect of cement silo is better than the other warehouse manufactured by other materials.

Get In Touch With

Español

Español