Steel Silo Technology and Grain Storage System in US

In order to guarantee food security, enhance the international competitiveness of grain and increase the farmer’s income, modernization grain logistics has been advocated in US in recent years. The key to realize the modernization grain logistics is to reform the traditional modes of grain storage and grain transportation. Steel silo with its low investment, short construction period and less area occupied has been the first choice for grain storage systems. After years of development, the technology of steel silos has been mature in America. There is a general tendency that more and more steel silos emerged to replace concrete silos. In Canada, America, Germany and other developed countries, steel silo has been the main type of silo that widely used in many fields. According to the statistics, steel silo has occupied 95% of the silo market in America.

The Situation of Storage Enterprise in America

In recent years, in order to cut down the expenditure, American government paid more attention to save the transportation cost and reduce the operation of public storage. At the same time, the scale of farmer storage has much expanded. According to the U.S. Department of Agriculture, in 2001, corn stock in all America is about 1.059 billion bushels. Among them, about 5 million bushels are stored in governmental storage system, which takes about 4.7% of the amounts. The total stock of sorghum, barley and oats respectively are 45 million, 92 million and 57 million bushels. All of them are stored freely in the market. As U.S. farmers turn in record grain crops in the autumn, many will have a powerful new tool- steel grain silos to help them avoid the lowest prices in years and gain more control over trade with giants such as Cargill Inc. There is a great demand of steel silos in American market to ensure the supply of grain. In the near future, more and more farmers will plan to build grain silos for grain storage, and grain bin manufactures in America have a perfect market prospect in America.

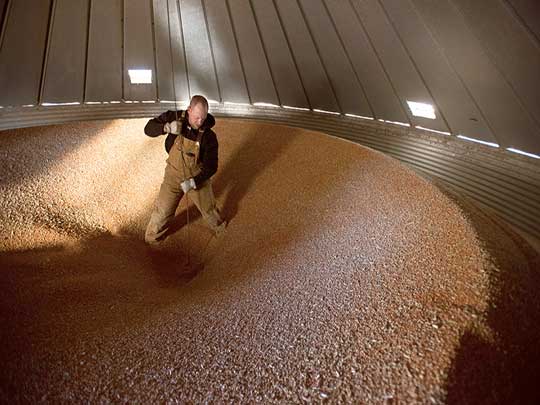

Wide Application of Steel Grain Silos on the Farm

Many farmers want to build on-farm steel bins to store grain. The bins you may see on a farm are often much more than oversized canisters; many farmers’ bins are equipped with a heating and drying system to bring the grain to the appropriate moisture content. Some bins, separate from those with dry-down capabilities, are strictly for long-term storage of the grain. Within advanced equipments, galvanized steel silos can perfect meet the need of moisture and ventilation.

Having storage bins on the farm is really convenient. For one, the farmer doesn’t have to worry about moving the grain elsewhere (such as to an offsite grain elevator) during harvest, thus expediting the harvesting process. Also, using their own storage bins can also eliminate the need to pay another facility to dry down the grain, the cost of which immediately cuts into the farmer’s profit. And yet another convenience is that the grain stored onsite can be used to feed a farmer’s livestock.

After the grain (and we’re talking specifically about field corn) is dried down and stored, it’s gradually sold for processing or for livestock feed. The prices of corn vary from year to year and are determined by the stock market. Taken into account is how much land is farmed with that crop, the projection of how many bushels will yield that year, the demand for that crop, and more.

How to Prolong the Lifespan of Grain Silos?

Although steel grain silo is made up of high quality metal against many corrosion and rust-resisting properties on its own, sometimes the base properties of the metal are not enough to keep the metal performing in the desired manner for extended periods. Many steel silo manufacturers in US offer additional metal coatings that can help extend the life of the silo long beyond the time in which it would break down without any special coatings.

These special coatings are designed to assist in a variety of different tasks and purposes, and most manufacturers will customize the coatings based on each individual factory’s need. After painted with these coatings on the surface, the silo can prevent the acid rain, the sunlight and rustiness. Now this technology has spread to other countries, which has greatly extended the performance life of grain silos all over the world.

Español

Español