Why We Choose Steel Grain Bins to Store Rice Husk

Rice husk is a thin shell outside the rice with humidity of about 12%. It contains 36% carbon, 0.48% nitrogen, 0.32% phosphorus, and 0.27% potassium, which is a kind of organic material difficult to ferment. As the main auxiliary material for making liquor, it is widely used in the brewing industry, at the same time it is also used in the feed industry, food industry, etc. With the large-scale and mechanized production of related enterprises, the demand for rice husk also increases. So we have higher requirements for its early transport, cleaning, and storage.The Common Method to Store Rice Husks

The storage forms of rice husk are various, which depend on the quantity, purpose, and location. General storage methods include traditional bag storage and horizontal warehouse storage, while these two methods bring great difficulties to mechanized production. At present, the steel grain bin is the first choice for many large-scale enterprises. Its high efficiency and safe running provide a good condition for the automatic operation of rice husk cleaning, transportation, and storage.

Bag Storage

Bag storage means filling the rice husk in jute or woven bags weighing up from 40 to 80 kilograms. These bags are usually stacked in pile and stored in a warehouse. During the storage process, we should note:

1. The stacked height of packaged rice husks should not be too high to prevent skidding from affecting storage stability.

2. They should be stored in a dry and airtight environment and placed on mats or other isolators to avoid absorbing moisture from the ground.

Horizontal Warehouse Storage

Horizontal warehouse storage refers to storing rice husks in bulk in a warehouse. This method is not convenient for the mechanized handling of rice husks, and we should pay attention to the moisture-proof and insect prevention problems.

Steel Grain Bin Storage

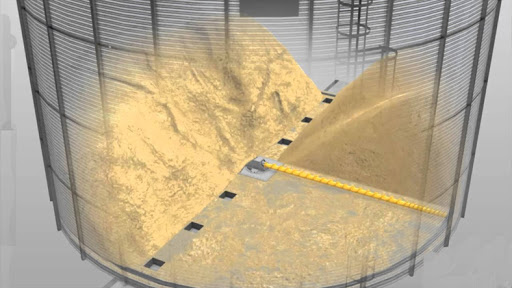

Large and medium-sized factories usually use steel grain bins to store rice husks. The capacity of steel grain bins is generally ranged from 20 to 2000 tons. It features good sealing performance, fast construction speed, and advanced material level measurement technology, which is consistent with the current trend of mechanized production in factories.

Advantages of Steel Grain Bin

The steel grain bin can be classified into spiral steel grain bin and welded steel grain bin. The former adopts the Lipp double-seaming technology, which is advanced in the silo construction industry. Flyer, as a steel silo manufacturer, offers various sizes of spiral steel grain bins. Except for lightweight, low cost, small space occupation, and short construction period, our spiral steel grain bins also feature:Sturdy and Durable

In addition to load force, the grain bin should also bear a considerable amount of pressure from grain. At the same time, the loading mode, loading height, and the side pressure of grain will also affect the storage performance of the grain bin. Therefore, the storage bin we selected must be sturdy and durable. The spiral steel grain bin produced by Flyer is made of galvanized steel with high strength and high corrosion resistance. This material extends the service life of the steel grain bin, except rice husk, it can also be used to store a variety of food crops.

Good Leak-proof and Moisture-proof Performance

The spiral steel grain bin adopts the Lipp double-seaming technology, which has an excellent sealing effect. It is effective in preventing moisture and rot of the rice husks. In addition, the steel grain bin is equipped with automatic ventilation equipment.

High Degree of Automation and Mechanization

At present, steel grain bins are equipped with the automatic conveying system, dust removal equipment, material level monitoring system, ventilation equipment, cleaning system, automatic alarm device, remote control system, and a series of automatic supporting devices. To a large extent, it improves the working efficiency and storage safety and also ensures the quality of stored materials.

How to Store Grain Husk by Steel Grain Bins

When we adopt steel grain bins to store rice husk, we need to carry out a series of processes, such as receiving, cleaning, measuring, loading and discharging, dust removal, ventilation, temperature measurement, material level measurement, etc. Compared with the traditional storage methods, mechanized and automatic equipment are used in these processes, which greatly improves the work efficiency and keeps rice husk fresh in long-term storage. Meanwhile, it also highly meets the production requirements of enterprises.

From the perspective of force analysis, because of the great friction resistance between rice husks, if the storage time is too long or the moisture content of rice husk is too large, it is very difficult to form a bulk flow when unloading. Therefore, for large-diameter steel grain bins, we will mount an unloading device. For small diameter grain bins, we usually design multi cone bucket outlets at the bottom of the bin. Each outlet releases rice husk in different periods to destroy the balanced support of rice husk inside the bin so that the rice husk can form a bulk flow.

Previous:The Application of Coal Silo in Port

Get In Touch With

Español

Español