Spiral Folding Principle

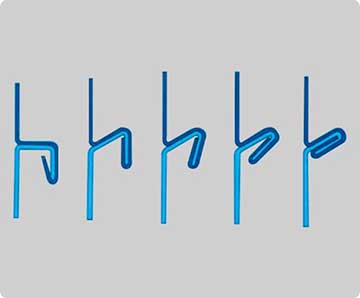

Flyer steel silo uses the most advanced spiral undercutting technology in the world. While being constructed, coil sheet of 495 mm in width is shaped through the shaping machine, bent by the bending machine, and then undercut to form a spiral protruding strip of 30-40mm width around the silo body, which plays a role of strengthening the silo body. Our shaping machine is also able to fold two different steel sheets together at once. Silo constructed by the spiral technology is also called lipp silo.

|

|

| zinc-plating roll bending | coil principle |

|

|

| bending process | bending undercut |

Steel sheet construction technology and process

To guarantee the quality of the entire project, we ensure every link from equipment locating, warehouse bending, roof installing, warehouse lifting, warehouse fixing, corridor installation and other auxiliary equipment is perfectly safe.

|

|

| equipment locating | warehouse bending |

- Equipment locating: locate equipment according to the diameter of the target silo.

- Warehouse bending: bend the warehouse to around 2-3m.

- Roof installation: install the warehouse roof after cutting the eave along the linear cutting by using of plasma cutting machine.

- Lifting the warehouse: lift the warehouse to the required height.

- Fixing the warehouse to the ground: fix the landed warehouse with embedded parts after withdrawing equipment.

- Installing corridor and other auxiliary equipment: install auxiliary equipment according to customer’s selected forms.

Español

Español