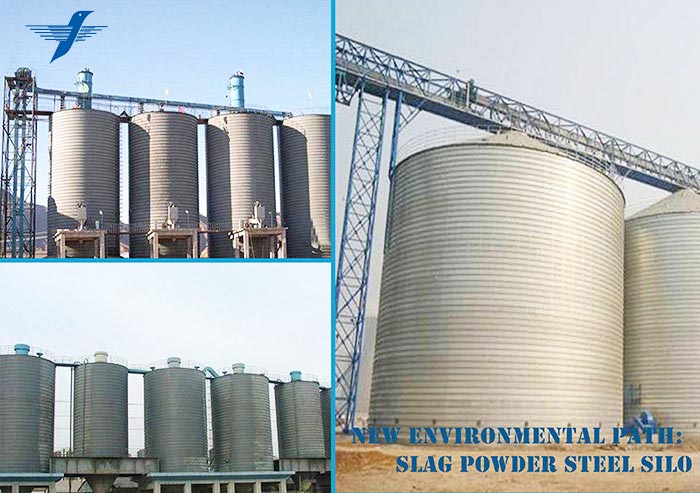

New Environmental Path: Slag Powder Steel Silo

The application of steel silo can effectively alleviate the waste of slag. In the past, because of limitation of technology developments, the added value and resource utilization rate of slag product are relatively low. Therefore, the slag was randomly piled up on the roadside or in the mountains, occupying a lot of land resources. A large scale of mining is bound to also result in scarcity of resources and easily arouse subsidence or earthquake. At the same time, the slag will also pollute the atmosphere. People probably have the respiratory tract disease due to a long time of the inhalation.

The usefulness of slag

There is no doubt that the slag has an important role in industrial production. Through relevant refining and deep processing, it can be made into slag cement, slag powder, slag Portland cement, slag wool, blast furnace slag, granulated blast furnace slag powder, which can save much energy consumption. In addition, the blast furnace slag can be used as raw materials of cast stone, ceramics glass, ceramic fertilizer and others.

1. Advantages of slag powder

When slag powder is used to equally replace cement content in a certain amount of cement concrete and cement products for various purposes, this can significantly improve comprehensive performance of concrete and cement products. As a new type of admixture material of high performance of cement concrete, it has the advantages of improving the properties of concrete. Here is specifically shown as below:

- It can improve concrete strength greatly to help to produce super high strength of cement concrete;

- It can effectively inhibit alkali aggregate reaction and increase the performance of reaction resistance of cement concrete, improving its durability;

- It can effectively improve the seawater corrosion resistance of cement concrete, especially suitable for seawater resistant engineering;

- It can significantly reduce the bleeding of cement concrete and improve the concrete workability;

- It can remarkably improve the compactness of cement concrete and improve the impermeability of cement concrete;

- It can significantly reduce the hydration heat of cement concrete and be suitable for mass concrete.

2. Blast furnace slag

Blast furnace slag is a kind of waste residue produced in the steel making process. According to the statistics of China, there is nearly 300 million tons of blast furnace slag produced in 2008. Its total output is increasing at the annual growth rate of about 10%. If it is piles up in open air all year round, this not only takes up a lot of land, but also causes atmosphere, soil and underground water pollution because of flying dust and heavy metal ions with the rain. The study has found that the chemical composition of blast furnace slag is similar to cement clinker, that is, blast furnace slag could be transformed into cement. The utilization of blast furnace slag in China is to seek to produce green cement with low cost and high quality. Our using 12 million tons of blast furnace slag can reduce the emission of 12 million tons of carbon dioxide and save 11 million tons of coal and 17 million tons of limestone, which can take great benefits to the environment.

Many large steel corporations have made good examples in the utilization of slag powder in China. The largest production line of slag superfine powder in the world has been built in China. In future, the slag will be totally recycled.

But when we completely use slag powder, we must face the storage question. Steel silo has become the first choice nowadays.

Storage of slag powder

1. The reasons of use of slag powder steel silo

A. When we use steel silo to store slag powder, we can reduce land area for the slag powder storage. Due to the closed storage, we can avoid the pollution of water resources caused by slag rain. The effective storage, we can make the slag powder change from solid waste into industrial raw materials.

B. We can put slag powder in a dry environment for storage because slag powder cannot get damp. Slight damp has no effect on its activity, but serious damp has great influence. The use of steel silo for slag powder storage can make it be always in a dry state.

2. The operations of slag powder steel silo

The finished product of slag powder will be sent into the silo through the air slide. The spiral structure of steel silo must consider climatic conditions, material characteristics and process characteristics. The finished products will be generally unloaded from the silo bottom by pneumatic device. The slag powder will be conveyed to package workshop at the side of the silo by air slide and the elevator. At the silo roof there is pulse bag dust collector. After it is put in operation, the emission concentration will be equal to or less than 30 mg/Nm3.

In each package workshop there is one rotary packaging machine. The maximum output of the system is 120t/h. And another one ton of bag packaging machine can be equipped with.

The product from the finished silo will be directly conveyed to the vibrating screen after its passing bucket elevator. After screening, it will be sent into the packaging silo. In the packaging workshop two bag type of dust collectors can collect the dust. After purification, the emission concentration will be equal to or less than 35 mg/Nm3.

3. High quality of slag powder steel silo

- More reliable working performance and cheaper price

- Water proof and moisture resistance.

- Long service life

- Professional design and manufacture.

- Make special customized construction according to customer's requirements.

Features of Our Silos

FLYER Company has rich experience in construction of modern large spiral steel silo for slag powder. Our slag silos have the features as below:

- They are equipped with safe valve to keep the balance of the pressure inside and outside the silos.

- It can be equipped level indicator to monitor storage level and capacity of the material.

- With the screw conveyor, the materials can be conveyed smoothly.

- They are fit for loading into any containers or trucks.

- Their excellent sealing performance can assure its efficient working performance.

If you have any problems or requirements, please contact with us freely. We will provide you with relevant specified information. Expect to set up sincerely friendship with you!

Get In Touch With

Español

Español