Grain Silo Development

Grain silo, also named grain bin, is a large grain storage container. It is widely used in grain-producing farms. If you take a drive through the countryside, you’ll see the tall, cylinder shapes that rise above the horizon.

Brief History of Steel Silo

According to the Archaeological ruins and ancient texts, silos were used in ancient Greece as far back as the late 8th century BC. The term silo is derived from the Greek Siros, "pit for holding grain". The first modern silo was invented and built in 1873 by Fred Hatch of McHenry County, Illinois, USA. In the early 20th century, steel silo has been widely used and almost replaced all the other types of silos in grain storage industry. So far, almost 95% of grain steel silos are used in the United States. However, Chinese steel silo didn’t achieved unparalleled development until 1990s.

Development of Grain Silo’s Material

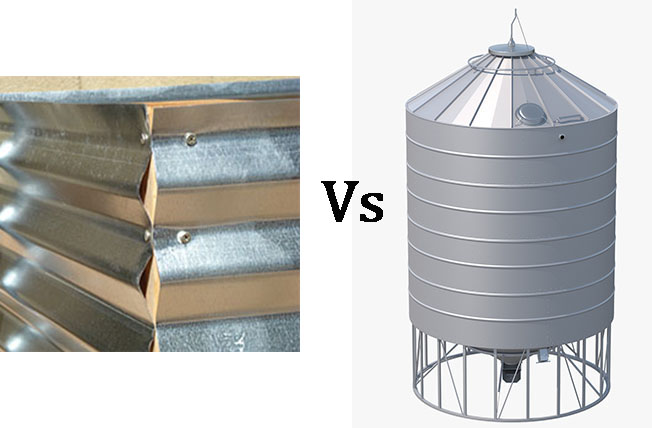

The first modern silo was a wooden and upright one. With the development of technology, steel silo replaced the wooden one . Dating from the early 20th century, steel silo has been widely applied in western countries. Now we use high quality galvanized sheet which is supplied by Handan Iron and Steel company. The sheet we used is in uniform thickness and galvanized with 275g/㎡of zinc. The materials we used are purchased directly from the manufacturer and they are all well-known brands.

Development of Grain Silo’s Technology & Equipment

So far, steel grain silo has experienced about three generations. The first generation steel silo appeared in the late 20th. The volume of it was very small and soon it was replaced. The second generation steel silo is also known as assemblage steel silo. The assemblage silo has been greatly improved in structural design and application. But it still exists some problems such as lacking of intelligent control on loading, unloading and storing materials and too much manual intervention. The third generation steel silo is known as spiral steel silo. The spiral steel silo uses special equipment for bending and seaming to ensure that all parts of the silo body process. And with the higher yield strength and tensile strength, we make it with high corrosion resistance.

Short duration is another advantages. We can provide a 5m per minuets’ shaping and bending speed. The weight of spiral steel silo is just as heavy as 1 / 6 of the concrete silo so the cost for the construction can be reduced a lot.

Now the spiral steel silo is widely applied in the areas of industry, agriculture and environmental protection and so on.

Development of Grain Silo’s Shape

Considering of the cost and efficient land using, most of the grain silos are built as cylinders. Compared with the square or rectangular structures, cylindrical structures are built more to resist the vertical pressures. Moreover, the cylindrical silos should be fitted tightly at the joints. Because it can not only increase the rigidity of the walls but also can make the silo airtight and easier to fumigate. For the square or rectangular structures, there are joints at every corner, which make sealing and fumigation more difficult. What’s more, harvested grain attracts rodents and insects, so the cylindrical buildings with fewer joints can prevent the pests effectively.

How do Grain Silos Work?

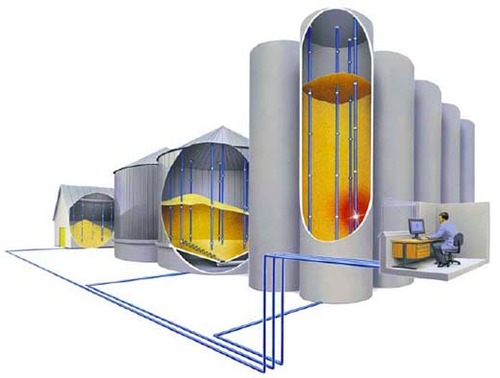

Most grain silos are very tall, so the key issue is how to transport these grains into the silo. Before the invention of motorized machines, the farmer loaded silos with grain manually. Now, for the most grain bins for sale, vertical elevator is widely used to fill grain bins. First the elevator transports grains to the top of the silo, then it makes full use of the gravity and causes grain to flow into the silo. When unloading grains, there is an opening at the bottom near the center. There is a machine called auger at the opening to transport the grain to other grain storage facility.

In addition, there is a temperature measuring device inside the grain silo. When grain temperature changes, a mobile blow ventilation device will be started for the safety storage. Therefore grains in the silo can be stored safely without any effect from outside.

Anyang Flyer steel silo engineering co., LTD is professional manufacturer and superior-quality steel silos provider. Our steel silos can be used to store cement, grain, chemicals, powders like mineral powder and fly ash and waste water treatment. Also we provide professional free design if you need.

Español

Español