Design of Steel Silo, Lipp Silo for Sale - Flyer

With the development of the times, spiral steel silos have walked slowly into our lives. We can find them in many places, but do we understand them? The design of steel silo has great influence on the service life of silo itself. Compared with steel silos from other manufacturers, our steel silo has unique advantages.

The steel silos are mainly used as the storage of cement, fly ash, slag, clinker, grain and other granular materials. After 2013, sulfuric acid liquid has been initially stored in the silos in China successfully. The steel silos have the higher application of construction with simple foundation and short construction period, which are not easily affected by weather factors.

We can see that the steel silos indeed have brought us a lot of help. And then we will talk about the precautions in their design and use together.

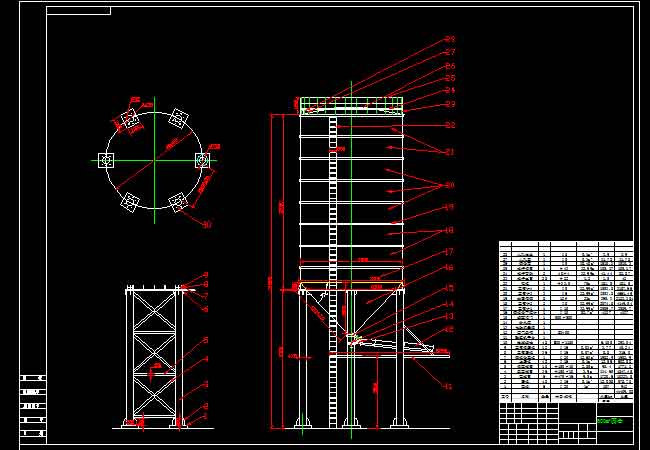

Designs of Steel Silo

Before the construction of the steel silo, we shall carry out accurate design calculation for details to do the best for laying a good foundation for the following construction. Especially for a spiral steel silo in the design, we must make the buckling analysis.

- The load and bearing capacity of the foundation shall be fully calculated by us in the design when the steel silo is completely charged.

- In order to obtain the reliable and practical data about the bearing capacity of foundation and soil density of the foundation, it is necessary to carry on the strict exploration to the steel silo.

- To set up the settlement observation area, we must calculate the difference between the load of the steel silo and the bearing capacity of the foundation based on the above No.1 and No. 2

- The range of foundation settlement must be equivalent to the height of the settlement area, otherwise the steel silo will not sink evenly.

- After the difference between the load of the steel silo and the bearing capacity of the foundation is calculated, we shall reach the bearing capacity of steel silo foundation through necessary construction according to the allowable value of foundation modulus and the soil density of the foundation.

- Because the cylinder body of the steel silo is affected by the load of axial friction and radial horizontal load, its instability characteristics are that the uplifts within certain areas of silo wall often occur, that is, the buckling of steel silo may cause a ripple in the height direction of the silo wall, which is similar to the sine curve, and then different ripple numbers may be shown differently in the circumferential directions on the silo wall. With further changes, they will cause the tilt or collapse of steel silo body.

- The instability of spiral steel silo is most likely to occur in the unloading process in which vertical pressure will cause structure damage of the steel silo by the friction of storage materials, which is the most common form. This is so-called buckling of cylinder body under axial pressure. In the calculation of the critical load, considering the various adverse effects and favorable factors of the internal pressure, the critical stress formula of the silo wall functioned by the interaction of vertical and horizontal pressure, its buckling form along the height direction occurs a sinusoidal characteristic with different number of the ripples due to its unique structure from the results of the buckling analysis. The fundamental reason is dynamic flow caused by storage materials. Although the design elements in the engineering design is rarely used to control the buckling analysis of the steel silo at present, in order to prevent the instability of the steel silo buckling, we are always suggested that the bending rigidity of vertical stiffeners of and the thickness of the wall shall be appropriately increased.

- Detailed design at the early times can effectively guarantee service life.

Español

Español