Advantages of Steel Silos for Grain Storage

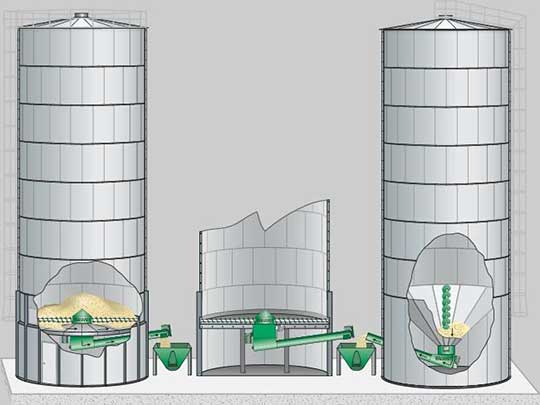

There are so many methods for grain storage, such as steel grain silos, concrete grain silos, storage warehouses, bag silos, and so on. Among them, steel grain silos and concrete grain silos are the most widely used in grain storage systems. Before planning a new storage project, all companies have to think about a question: which kind of grain storage system should I choose? Building a concrete silo, a steel silo or a warehouse? To answer this question, we will point out the key differences between steel grain silos and concrete grain silos.Production Process

All parts of steel silos are manufactured in factories, so the quality can be totally guaranteed and controlled, whereas cast in place concrete silos involve more variables such as concrete delivery and weather. When building a concrete grain silo, you should have to bear in mind the useful life of concrete before use is less than 2-3 hours. After this period, the optimal characteristics of concrete would be changed a lot, which causes unnecessary waste of resource.

Grain Silo Design

The slip frame concrete process is further complicated by the fact it is a dynamic or continuous process. Rebar placement, concrete quality, etc., all affect the final product. Also, field supervision plays a really serious part in concrete silos: more people working on site, longer period of commissioning (due to weather conditions and environment conditions) and, ultimately, higher costs.Concrete silos can be taller than steel silos but these ones have bigger diameters so the total capacity is highest. For this reason concrete silos are only more suitable when the space is really limited.

It is easier to erect steel silos and also to install accessories like doors, ladders, samplers, etc.

Steel structure is more flexible, which promises steel silos have better behavior in case of earthquake. When earthquake is coming, concrete grain silos may fall into ruins because of the loose structure, while steel grain silos won’t. So to be safe, steel grain silos are suitable for different geographical environment.

Regarding airtight, both structures of steel silos and concrete silos are normally airtight if the openings are properly sealed.

Construction Cost

Steel silos generally give you greater storage capacity per dollar. They tend to be more cost-effective because of the higher storage capacity. While the price of steel is higher than concrete, the construction of steel grain silo is much easier than concrete grain silo. What’s more, low maintenance cost is an important reason to choose steel grain silo.Aeration Treatment

It is easier and more effective to do aeration in steel silos. Aeration horsepower is a non-linear function of grain depth. It is often impossible or impractical to provide the same airflow in tall concrete silos that could be obtained in shorter and wider silos (the case of steel silos). A higher grain depth also leads to a higher heat of compression in the aeration system. This means it takes a lower outside temperature to achieve the same grain temperature, making early aeration more difficult.

Grain Silo Foundation

When building steel silos, you don’t need the silo to be enough firm to support the weight of structure. Sometimes steel silos can be built on land that doesn’t have the higher load-bearing capacity needed for concrete.

There are many details and variables in silo projects and every type of grain storage has pros and cons. The right choice is the one that fits in your infrastructure strategy and practical requirements.

Get In Touch With

Español

Español